What is Advanced Manufacturing?

by Kirk Rogers

While a bit more shut in than normal this spring, I enjoyed a number of books that have been waiting for me in the nightstand for some time. “How to: absurd scientific advice for common real-world problems” by Randall Munroe kept me smiling while considering how creative you have to be to coordinate real world problems and absurd scientific solutions. The SME book “Introduction to Advanced Manufacturing” by Harik and Wuest has been a nice way to refresh some manufacturing fundaments and perhaps learn some new ideas that I can apply with our clients. It’s also got me thinking about Manufacturing and what that means.

What constitutes manufacturing?

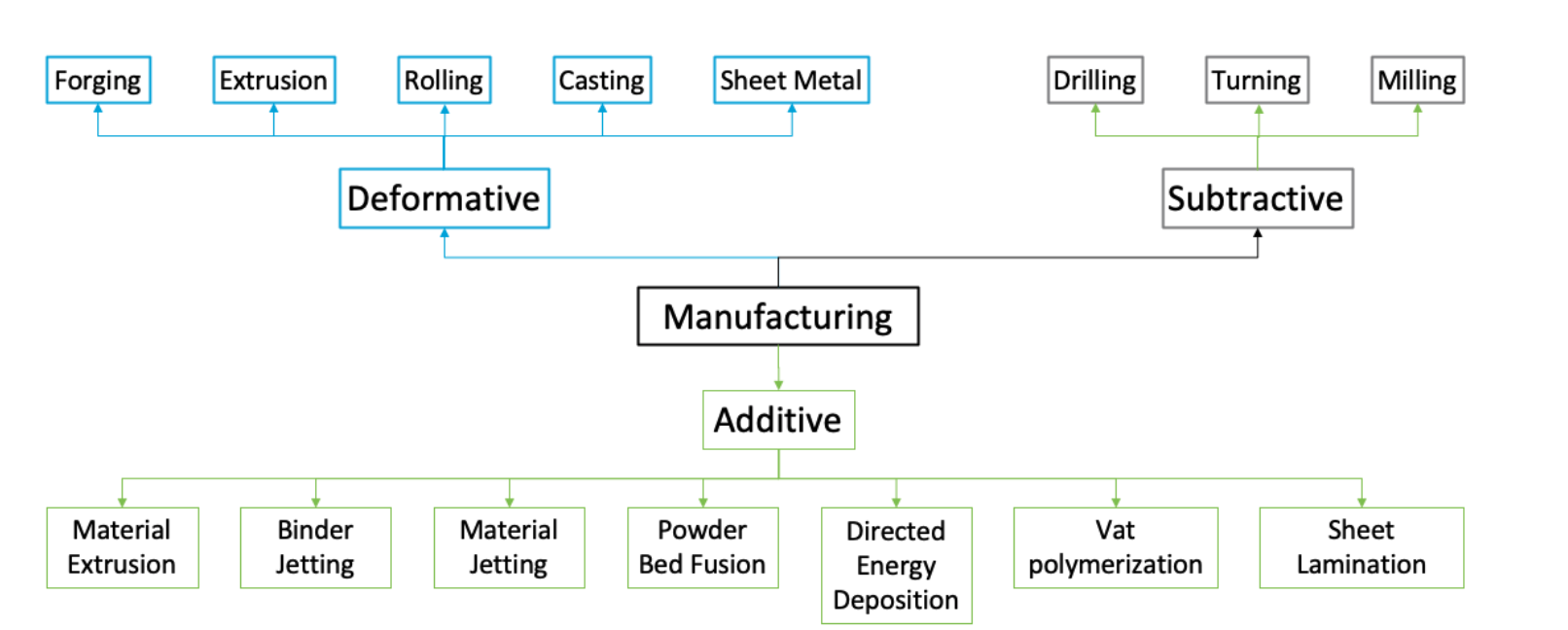

The Introduction to Advanced Manufacturing defines manufacturing by a simple taxonomy, Deformative, Subtractive and Additive. Classically, these would all be a subset of processing that is required to make parts vs assembly, which is used to make final product. Breaking down those subsets to the next level we arrive at something like this:

Manufacturing Taxonomy, adapted from Figure 1.7 of Introduction to Advanced Manufacturing.

Then what constitutes Advanced manufacturing?

A number of years ago, the President’s Council of Advisors on Science and Technology (PCAST) report about advanced manufacturing said this:

“The advanced manufacturing entity makes extensive use of computer, high-precision and information technologies integrated with a high-performance workforce in a production system capable of furnishing a heterogeneous mix of products in small or large volumes with both the efficiency of mass production and the flexibility of custom manufacturing in order to respond quickly to customer demands.”

The PCAST definition today sounds to me like a precursor definition to what now seems to be commonly referred to as industry 4.0. That’s interesting, but after many years smelling coolant in the morning I tend to think more from the process perspective.

Process Perspective

Sophisticated design and development process

Precision measurement systems

Integrated information technologies

Advanced robotics such as collaborative robots

Advanced Automation

Additive Manufacturing

Control systems with real-time process monitoring and feedback loops

Requires elaborate or complex equipment

This perspective is more traditional manufacturing on steroids. New tools enable established industries to dramatically change the way their business operates. For example, last year Machine Metrics presented one example implementation of their automation software paid for itself in 11 days! What an ROI!

To me that means that any manufacturing that adopts modern, efficient & flexible technologies is advanced manufacturing. The feed-back and feed-forward of information for real-time decision making is key as is making the process data actionable. The adoption of technology and the ability to use it at a pace to remain competitive in one’s industry = Advanced Manufacturing.