TBGA Toolbox

Grow your business with the help of TBGA expertise, tools, and models.

Grow your business with the help of TBGA expertise, tools, and models.

TBGA combines industry data and knowledge, deep process expertise, and data analytics to create proprietary tools, models, and processes that help our clients navigate the landscape with more insight.

Our team of engineers, material scientists, and media specialists have broad firsthand expertise. We have qualified AM parts for medical, aerospace, and transportation that bring expertise to our client's journey.

While there are a variety of AM technologies, this tool provides users with a way to analyze how these three elements work together to define the process: (1) How do you form the LAYER? (2) How is the ENERGY applied? (3) How is the MATERIAL applied?

The AM Maturity Model describes the additive manufacturing learning process as applied to product development. As machine, material and design skills mature, so does the ability to utilize AM to maximize part requirements. This tool is a valuable asset for those embarking on the AM journey.

TBGA provides a unique view for engineers as they must balance the restrictive and opportunistic aspects of AM for success - do you modify or design? It's key to note, Designing for AM = Modifyign for AM (MfAM) + Design for AM (DfAM).

Using the three elements from the Simplified View of AM, we are able to categorize and define each technology by "family groups". This grouping helps provide context to technologies that fall outside the traditional seven such as Cold Spray.

Is your company "ready" to adopt AM? The AM Readiness Model evaluates where your company currently stands on your AM journey by identifying capabilities of machine, material, digital, and people knowledge. This tool guides future areas of AM growth within an organization.

Mass, Surface Finish, Criticality, Size, Materials - all impact which additive manufacturing process to use. Within this tool, TGBA highlights how the AM process will have to be capable to meet form, fit, and function to meet requirements.

As AM has evolved, the distinct characteristics of the technologies have overlapped by definition. TBGA has broken down the definitions to identify four areas that all AM technologies have in common: Machines, Materials, Digital, and People.

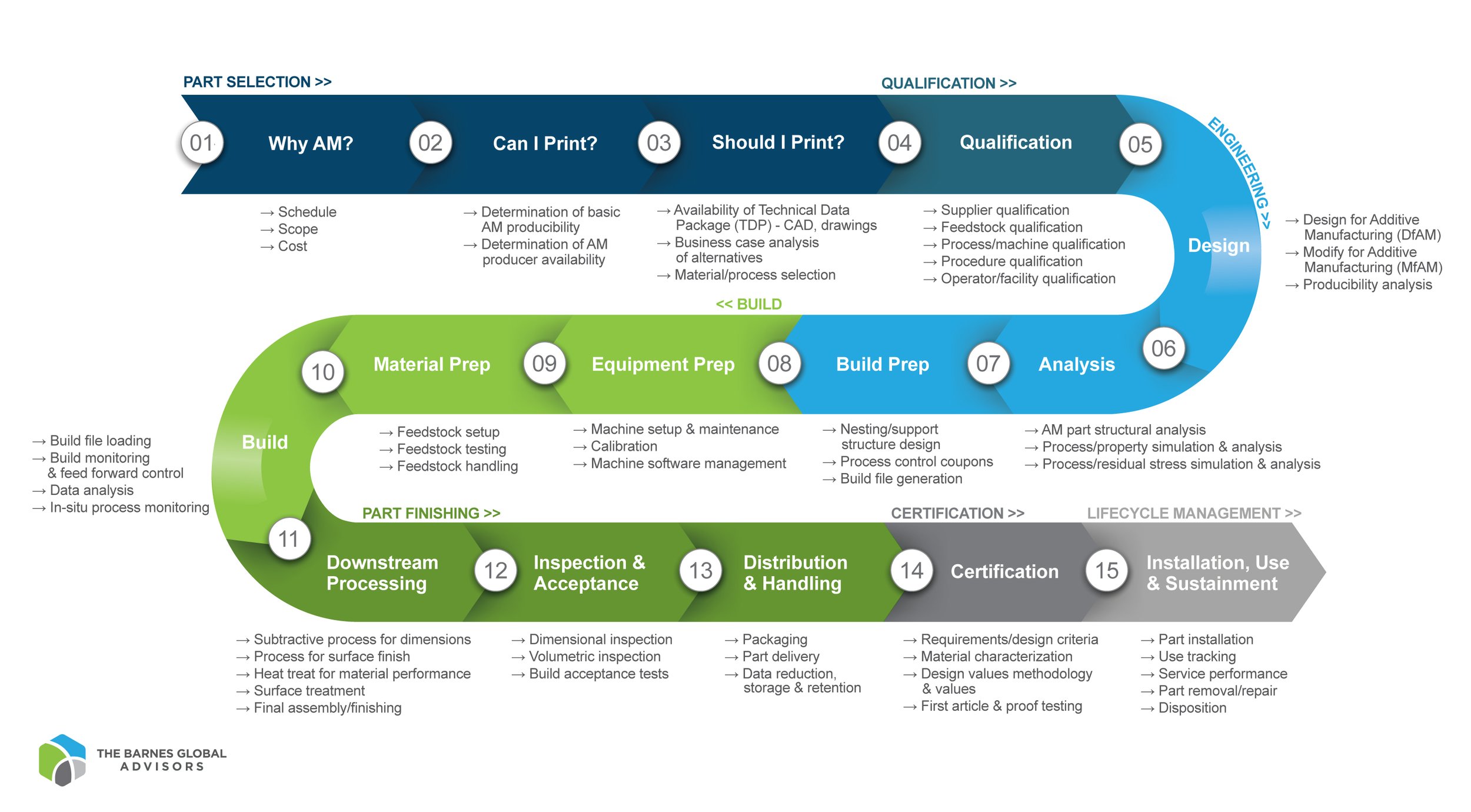

The "Can I Print/Should I Print" questions are key when introducing AM. This model walks you through each crucial step of the value chain. It's an indispensable tool designed to ensure that every part meets the stringent requirements necessary for successful installation and deployment.

The Qualification Framework illustrates how all aspects of the qualification are part of certification too. The framework is dominated by requirements that must be met before moving to part/performance qualification and system certification.

We help clients explore the art of the possible using the best-in-class software solutions.

Combining our expertise in MfAM and DfAM, we help create designs only possible in AM.

Our cost models help clients understand the expected costs of AM parts, trade machines, and technologies.

Our machine learning algorithms are tuned to work with small data sets found in process development and qualification. These tools are used to accelerate development of optimum process parameters for AM machines.

Improve AM facility performance in material, equipment, employee and facility safety, and security with the TBGA Essential Elements of Facilities Safety tool.

By incorporating data gathered by careful tracking of industry data and predictive modeling, our Integrated Demand Model estimates the global AM market for machines and feedstock.

Drawing on decades of powders production experience and capabilities tracking, the Powder and Atomizer Model helps assess process cost implications and production capacity.

Using operating costs, utilization data, and market demand pricing, we have created models to predict revenue potential and investment profiles of AM equipment.

Improve performance and stimulate business growth through advanced manufacturing.

Upskill your workforce with world-class applied learning from industrial AM experts.